Over the years, I’ve made a habit of putting together write ups at the conclusion of completing specific Heckler and Koch Armorer Courses. I made a conscious decision to just focus these on the weapons the majority of HK fans would not be familiar with, specifically the LE/Mil weapons. But this week, while attending recertification on some of the pistols, I decided I’d go back and combine my notes, photos and memories of this and my previous training, along with my own studies and experience maintaining these weapons through my company in order to provide a report covering the pistols that carried the company from the early 1990s right up to its latest release of the new VP series. I’m confident that you’ll enjoy this and that even the most ardent Heckler and Koch fan will learn something here they did not know about their favorite pistols.

Since much of the design features created from the development of the USP have carried over to the P2000, HK45 and P30 series line, I will focus the discussion of those following pistols on their continued upgrades and advancements instead of regurgitating the same features already covered in description with the USP series.

So, let’s set the stage by winding back the clock to the end of the 1980s. This decade of excess ended with what was known as a period of hard times for the company. Over-extended with the G11 program and their hopes to secure major military contracts falling apart with the challenges associated with the weapon design itself and the fall of the Berlin Wall, the company was placed up for sale. After a purging of a huge amount of personnel, both skilled laborers and institutional knowledge and a restructuring and cutting away of what was seen by the new ownership as costly distractions, a new focus was needed. That focus was on needing to find a new product that would keep their production lines going and that product would need to be much more simple and cost effective to be produced. As such, there was a forced diversion from the earlier stamped steel construction and a mandate towards what we affectionately refer to as “revolutionary space age polymer construction”. And knowing that there is no greater target rich environment for sales of firearms than the US civilian market, with only the P7M series pistols in that civilian catalog and with the loss of their entire rifle line to the 1989 assault weapons ban, they chose to focus their efforts on a new pistol for the Americans. Thus, what came to be termed the USP or Universal Self-loading Pistol, was jokingly referred to within Oberndorf as the “US Pistol.” It was designed in concert with an intended submission for the FBI’s 10mm service pistol contract going on at the same time, but their selection was completed before the HK pistol.

Along with a directive for polymer construction, a market study was undertaken to see what features the American market was most interested in. Prime among these, was an affection for the tried and true Browning short recoil system. This also appealed to HK designers, as this system is simple, reliable and cost effective to produce. From there, they set out to maximize modularity to create a pistol that could be modified to the desires of the shooter.

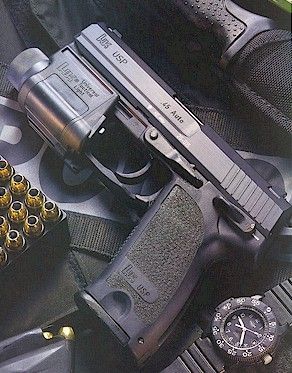

Groundbreaking at the time, this was also the first pistol to be developed with an accessory rail for mounting lasers and lights. Later criticized as being proprietary and not accessible to a wide range for products that were being released at the time, the design predates an “industry standard” or picatinny system and should be viewed retrospectively as revolutionary for the time. Below is an early "gun mag" photo from the USP45 release, shown with the UTL mounted.

![Image]()

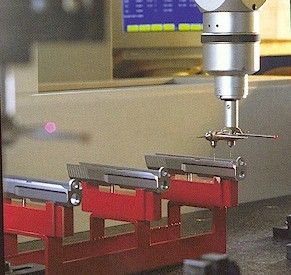

The heart of the USP, like all HK weapons, is the barrel. If there is one thing that HK does best, it is making the highest quality, longest lasting barrels. For the pistol line, barrels come in as blanks, where they are then inspected, deep drilled and then mandrels are inserted with either polygonal or conventional lands and grooves (initially, the USP was offered with lands and grooves, but after the first two years, that was changed to polygonal). Then, 9 barrels at a time are placed into one of the cold hammer forging machines, where 4 hammers take action, imparting 140 tons of pressure per beat and 1000 beats per minute. Once complete, these pistol barrels then have their chambers milled in another machine.

![Image]()

The slides are milled as well, from a solid block of steel and as a cost saving measure, the scraps from the chamber and slide milling process are sold back to the steel company. Designed around the higher pressures associated with the .40 S&W cartridge, the USP slide is rather large. Notable with the 9mm variant, that required slightly less weight to cycle reliably, a lightening cut was made into the underside of the slide (shown below). It was done both near the front of the slide, in an oval shaped cut out as well as the rear of the slide, next to the firing pin tunnel, opposite side of the extractor.

![Image]()

As reinforcement in key stress areas, laser hardening was placed in two locations: first, on the front edge of the ejection port area, where the barrel locks into place, in order to prevent cracking and chipping, and second, at the end of the firing pin tunnel, where the hammer makes contact with the firing pin. Finally, the extremely tough finish is applied, a nitro carburization process, where heat is applied with the finish, while oxygen is injected to aid in providing a better seal.

![Image]()

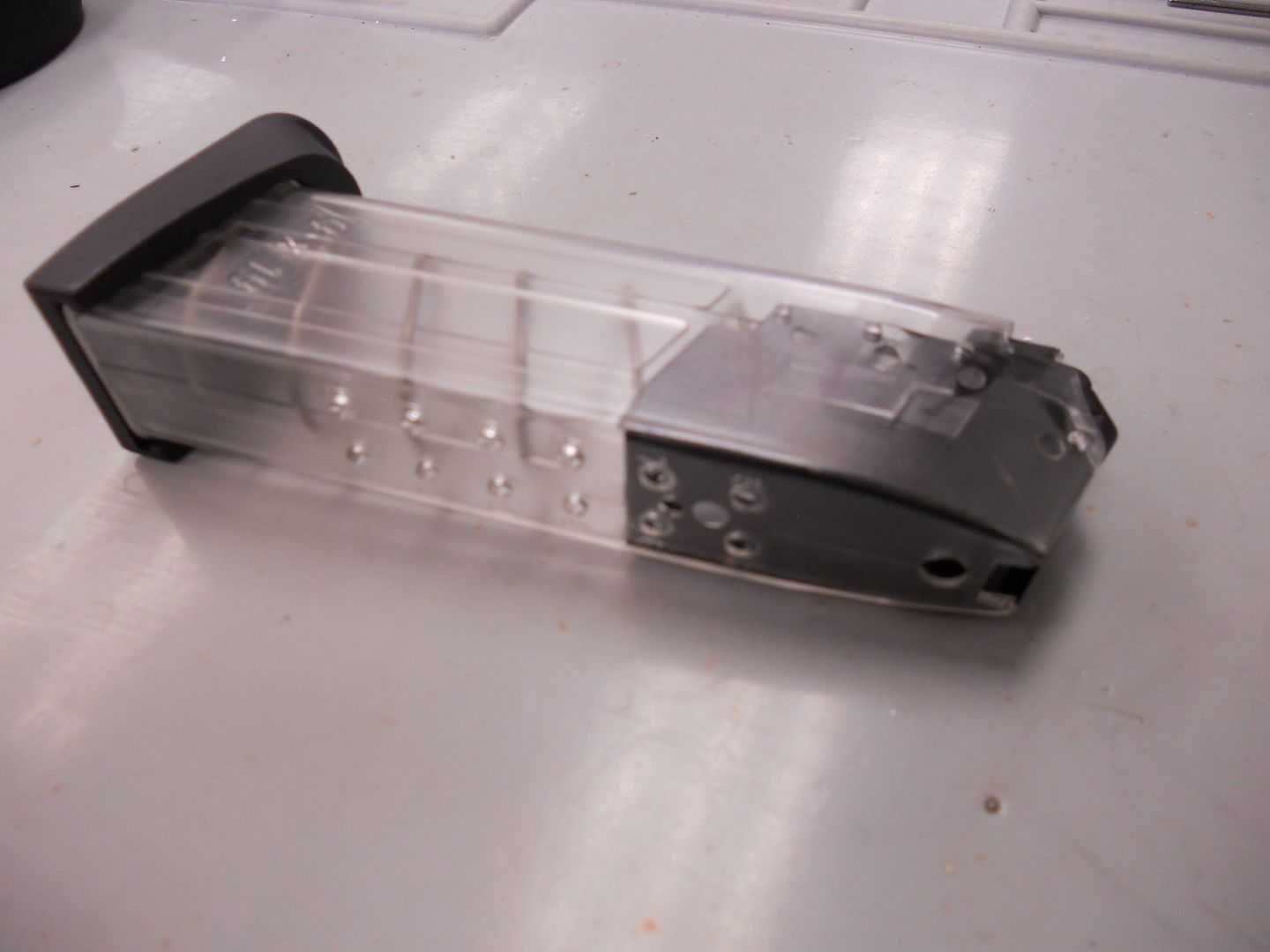

The receivers are created by pouring the polymer pellets into a clam-shaped mold, but to add strength in key areas, two steel inserts, one for the fire control assembly/ejector and one for the locking block and serial number plate, are injected just prior to pouring the mold. Though the .45 variant and compact USPs all are issued with steel magazines, the full size 9mm and .40 S&W variants have polymer magazines, but with steel inserts at the top portion, adding strength to the feed lip area (see polymer cutaway photo below).

![Image]()

Also, revolutionary at the time, was the incorporation of a relief port, just behind the breach face. Shown below, this area helped prevent “gunk” from building up within the firing pin channel and binding up the firing pin assembly, mainly found with poorer quality ammunition and lacquered bullets. Though not introduced into the USP until a few years after production began, so successful was this feature, that HK has since carried it over to their successive pistol line, as well as their long guns.

![Image]()

Once complete, each USP fires 17 rounds. The first 2 are for proofing and when complete a representative from the Ulm proof house then authorizes the proof stamp, the famous antlers, to be struck. The remaining 15 rounds, 5 for accuracy and 10 for reliability, are then fired. For accuracy, on the full size USP, 4 of 5 shots must not exceed 4.8” at 25m, whereas with the compact model, that spread is allowed to increase to 6.8”. For those who wonder about what hold is used when zeroing the USP at the factory, it is done with a 6 o’clock hold, POA/POI at 25m, firing FMJ ammunition.

Sight adjustments are made by the front and rear sights. Changes in elevation are made by removing the front sight and exchanging it for either a lower or higher sight. To raise the POI, replace with a shorter sight. To lower the POI, replace with a taller sight. Sights are offered in .2mm increments and each change of .2mm will affect the POI by 2” at 25m. For windage changes, simply shift the rear sight in the direction you want the round to shift. Sight heights are generally inscribed on the underside of the sights, but if you need to find out the height of your sight and that description is omitted, simply measure from the base of the sight to the top (see photo below).

![Image]()

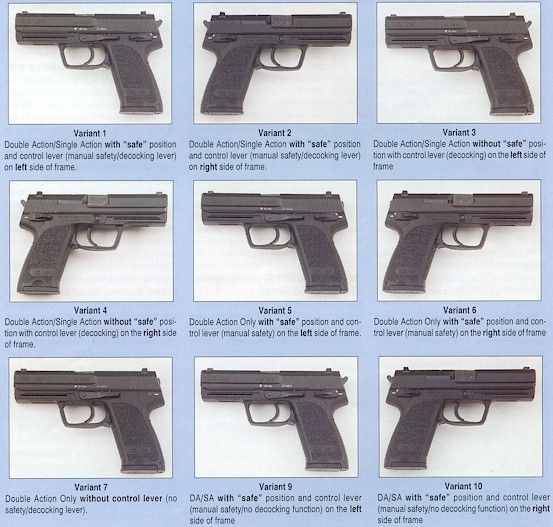

When released, first in .40S&W and then shortly after in 9mm, the pistol was a huge success in the US market. Soon after, compact models followed of each, then came the full size and compact .45 variants. As mentioned previously, modularity was a key feature. The USP series is capable of being converted to 10 different variants, allowing traditional double action/single action, left and right side control levers, decock only, safety only, ambidextrous safety, and even a double action only (DAO), which due to its extremely heavy trigger pull was not a popular option and later discontinued. Yet, as the popularity of the pistol increased and more and more law enforcement purchases and contract began to materialize, a desire for an improved DAO system was realized. Enter the LEM or Law Enforcement Modification.

Developed especially for the US Immigration and Naturalization Service (INS), to improve trigger performance and reduce the trigger pull weight of DAO pistols, it quickly became a desired option and helped secure HK with the largest non-military pistol contract they had ever received. After 2001, it was also offered for the civilian market.

USP DA/SA and LEM Cutaway Pistols:

![Image]()

Since I regularly receive questions relating to understanding the operation of the LEM system and equally see many inaccurate descriptions presented “online”, I’ll explain here how it works:

The hammer in the LEM is a two-piece hammer comprised of a cocking piece (not visible when the pistol is assembled) and an external (visible) bobbed type hammer. The cocking piece and hammer are rotated rearward on the hammer axle when the slide moves to the rear. The LEM uses the rearward movement of the slide during loading and firing to fully compress the hammer spring instead of relying on the trigger pull in a conventional DA or DAO to compress the spring. The cocking piece is held in position by the sear and the hammer spring has been fully compressed by the hammer strut. Pulling the trigger rearward overcomes the trigger pull weight and disengages the passive safeties and the sear releases the cocking piece rotating the hammer forward on its axle under pressure of the compressed hammer spring imparted through the hammer strut to strike the firing pin.

As many have experienced, the LEM has many great features and benefits. I believe these to be the most significant:

-No external de-cocking or safety levers are needed (although external safeties can be assembled on some models if required, such as the USP).

-Consistent DAO trigger pull weight is reduced to approximately 7.5-8.5 pounds and a lighter trigger weight of approximately 5.5 pounds is also available.

-A safe length of free travel (slack) and a second stage of slightly heavier but consistent pull with every round fired.

-Short, consistent trigger reset distance normally associated with a single action (SA) pistol, enhancing the speed and accuracy of multiple follow up shots.

-Reliable, heavy hammer spring and hammer drop initiating the firing pin, even in adverse conditions.

-Fail safe, true, double action mode, should a primer fail to detonate on the first strike of the firing pin by simply pulling the trigger again.

Shown below is an early presentation of the multiple variants of which the USP can be set up. The introduction of LEM has since replaced the earlier DAO variants.

![Image]()

Safety is always a hallmark of Heckler and Koch weapons, and with the USP they raised the bar again. There are no fewer than eight safety measures in place on the USP:

-Disconnector: Ensures the slide is in battery, preventing out of battery fire. If the slide is more than 2.5mm back, the disconnector pushes down on the trigger bar, dropping it out of contact with the catch and thus, the sear.

-Firing Pin Spring: Preventing slam fire, it provides tension against the firing pin that must be overcome before the firing pin can strike the primer on a chambered cartridge.

-Firing Pin Block: Mounted horizontally within the slide, this prevents the firing pin from moving forward until the trigger is pulled. When the trigger is pulled, the reward movement of the trigger pulls the trigger bar forward, where it makes contact with the catch, forcing it up and in contact with the firing pin block, then pushing it up and out of the way of the firing pin.

-Catch: Mounted next to the disconnector, it disengages the firing pin block when the trigger bar is pulled (as described above).

-Sear Actuator Latch/Drop Safety: Dual purpose part that blocks the hammer from making contact with the firing pin until the trigger has been pulled. Mounted adjacent to the catch, when the trigger is pulled and the trigger bar pulls the catch up, pushing the firing pin block out of position, this part is correspondingly forced down. The downward movement drops the rear tip out of contact where it blocks the hammer and into a recess at the base of the hammer, allowing it to now move further forward and strike the firing pin. At the same time, at its opposite end, it makes contact with the sear roll pin and pushes the sear forward and out of contact with its interface point on the hammer (or contact piece, in LEM), allowing the hammer, under tension of the compressed hammer strut spring to fall forward and strike the firing pin.

-Safety: The external safety, as part of the control lever, prevents the trigger from being pulled until it is disengaged. When disengaged, a cavity in the hammer axle is presented to the catch, which allows for it to pivot under pressure from the trigger bar and trigger itself.

-Rubber Hammer Insert: Designed to both lighten the overall weight of the hammer (allowing for lighter overall trigger pull) and dissipate energy if the weapon is dropped on the hammer (better surviving drop tests, described shortly).

-Lock Out Device: The incorporation of the lock out device that has been built into the lanyard loop, when engaged, prevents the compression of the hammer spring and downward movement of the hammer strut.

*Of note, there is often much confusion surrounding the correct description of the Catch, Control Lever and Sear Actuator Latch. This is because of the multiple roles these parts fill and the fact that in initial introduction, they were a one piece item, simply referred to as the Catch. When, a couple years into production, this single part was separated into two parts, the confusion began. Mislabeled in multiple documents (owner’s manuals, maintenance manuals, spare parts lists and charts), they are usually referred to as the Catch or Control Lever, which as described above, is related to disengaging the firing pin block and the Catch, Sear Actuator Latch or Drop Safety, which blocks the hammer and pulls the sear out of its interface point with the hammer (or contact piece, in the case of LEM). Confusing, but it is best to be clear in describing the action the part provides during the discussion.

This is also a good place to discuss the Drop Test. This series of tests is actually a requirement from three different entities and is tied heavily into being able to be competitive for LE and military contracts. (Apparently people drop their pistols often and end up shooting themselves or others). This test, involves taking an empty cartridge casing, filling it with modeling clay and then inserting the casing into the chamber of the pistol. Then the pistol is dropped six times, once on the magazine, once on the sights, then on the back, front and each side. After each drop, the cartridge is inspected to see if the firing pin has imprinted on the clay in the position that would be the cap. For the NIJ Drop Test, the test is conducted from a height of 1 meter and dropped onto a hard, rubber plate. For the NATO Drop Test, the test is conducted from 1.5 meters and dropped onto concrete. And for the German TR Drop Test, the height is raised to 2 meters and dropped onto a steel plate. Often, people complain about why HK does not offer lighter trigger pulls on their USP and other pistols and the answer is from the results of these tests. HK designers have found that modifying internal components in order to provide a trigger pull of less than about 3.5 pounds makes it very difficult to pass these tests.

Another unique feature of the USP, actually designed as part of the MK23 program that was preceding the USP development, is the recoil reduction system or dual recoil rod assembly. The second stage helps significantly reduce the energy imparted on the receiver during firing. Activated twice during the 8 step cycle of operations, it allows the USP to exceed sustained use of +P and +P+ ammunition. Not found in the compact models, simply due to size limitations, instead, there you will find a polymer absorber bushing, which serves to prevent the tang on the front of the slide from impacting the receiver during recoil.

Another neat modular addition that was offered with the 9mm and .40 S&W USP full size pistols is the Jet Funnel Kit. This steel magazine well extension provides more grip space as well as a more effective insert point for rapid magazine changes. Adding it to the pistols prevented the use of the standard magazines, but instead incorporated either 18 rounds magazines for the 9mm and 16 round magazines for the .40 S&W. The photos below show the kit and the kit installed.

![Image]()

![Image]()

This photo shows the standard USP 9mm full size magazine, the original semi-translucent polymer Jet Funnel Kit magazine and the current production, steel Jet Funnel Kit magazine.

![Image]()

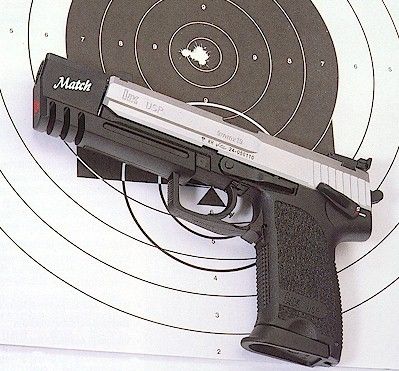

With almost 25 years of production and an extensive line of models that followed the initial full size model, including the Match, Elite, Expert and Tactical, it is clear the USP is a solid fan favorite.

Shown below is an early promotional photo of the Match.

![Image]()

Here is an Elite on my workbench.

![Image]()

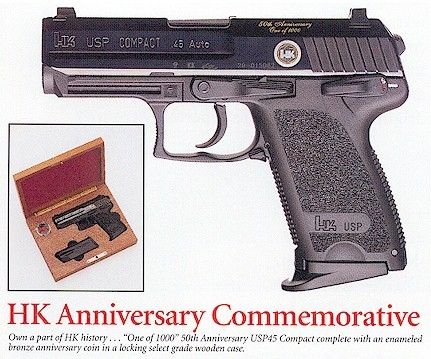

And here is an advertisement for the limited edition anniversary model USP Compact.

![Image]()

Lastly, shown here is the USP Compact Tactical, with KAC suppressor, the predecessor to the HK45 Compact Tactical, later adopted for service with Naval Special Warfare Command.

![Image]()

*One note regarding the Tactical variants (9mm, .40 S&W and .45) due to the additional pressures associated with firing suppressed, these pistols are provided with specific caliber upgraded recoil rod assemblies. These can be identified by a single band or “cut” neat the end that locks up with the locking block. Though many owners are unaware of this upgraded part, and just drop in aftermarket threaded barrels to their standard USP pistols, doing so could cause permanent damage to their weapons.

Difficult to identify in this photo, but the top recoil rod assembly is the standard USP type, while the bottom one, with the circular band at near the end is the Tactical model.

![Image]()

And through this long period of production, HK has literally upgraded almost every internal component of the USP to improve its already stellar reliability and keep it current. This is one of the reasons why, even with so many newer options available from HK and other companies, they still receive regular orders for both new sales to the LE community and requests for this Armorer training.

For the Armorer training and maintenance of these pistols, HK provides several tools and gauges in order to ensure specific parts are within spec to ensure safe and reliable operation. Several are shown below. What I have found most impressive, specifically relating the bore and chamber “no go” gauges is just how many rounds would have to be fired before a barrel would be considered out of spec. Clearly, the amount of erosion would require a round count well north of 75,000.

![Image]()

Before moving on, I would be remiss to not mention the P8 and P10, German service variants of the USP. Of course, within HK USA, it is found amusing that the “US Pistol” would find service within Germany. From the USP, there are only a few minor differences. First, and most obvious, is the reversal of the control lever, with Safe being down and Fire being up. This was done because the German police and military units were, at the time, transitioning from post WWII Walther designs, which incorporated a slide mounted control lever in the same orientation. Next, the magazines (also shown below) are of a semi-translucent construction. And third, due to German directive, the barrels are conventional lands and grooves instead of polygonal.

![Image]()

Due to a character limit on this Forum, I was forced to split this report into two parts. Please find Part 2 here:

http://www.hkpro.com/forum/teufelsh...ufelshund-tactical/221991-notes-usp-p2000-hk45-p30-armorer-course-part-2-a.html

Since much of the design features created from the development of the USP have carried over to the P2000, HK45 and P30 series line, I will focus the discussion of those following pistols on their continued upgrades and advancements instead of regurgitating the same features already covered in description with the USP series.

So, let’s set the stage by winding back the clock to the end of the 1980s. This decade of excess ended with what was known as a period of hard times for the company. Over-extended with the G11 program and their hopes to secure major military contracts falling apart with the challenges associated with the weapon design itself and the fall of the Berlin Wall, the company was placed up for sale. After a purging of a huge amount of personnel, both skilled laborers and institutional knowledge and a restructuring and cutting away of what was seen by the new ownership as costly distractions, a new focus was needed. That focus was on needing to find a new product that would keep their production lines going and that product would need to be much more simple and cost effective to be produced. As such, there was a forced diversion from the earlier stamped steel construction and a mandate towards what we affectionately refer to as “revolutionary space age polymer construction”. And knowing that there is no greater target rich environment for sales of firearms than the US civilian market, with only the P7M series pistols in that civilian catalog and with the loss of their entire rifle line to the 1989 assault weapons ban, they chose to focus their efforts on a new pistol for the Americans. Thus, what came to be termed the USP or Universal Self-loading Pistol, was jokingly referred to within Oberndorf as the “US Pistol.” It was designed in concert with an intended submission for the FBI’s 10mm service pistol contract going on at the same time, but their selection was completed before the HK pistol.

Along with a directive for polymer construction, a market study was undertaken to see what features the American market was most interested in. Prime among these, was an affection for the tried and true Browning short recoil system. This also appealed to HK designers, as this system is simple, reliable and cost effective to produce. From there, they set out to maximize modularity to create a pistol that could be modified to the desires of the shooter.

Groundbreaking at the time, this was also the first pistol to be developed with an accessory rail for mounting lasers and lights. Later criticized as being proprietary and not accessible to a wide range for products that were being released at the time, the design predates an “industry standard” or picatinny system and should be viewed retrospectively as revolutionary for the time. Below is an early "gun mag" photo from the USP45 release, shown with the UTL mounted.

The heart of the USP, like all HK weapons, is the barrel. If there is one thing that HK does best, it is making the highest quality, longest lasting barrels. For the pistol line, barrels come in as blanks, where they are then inspected, deep drilled and then mandrels are inserted with either polygonal or conventional lands and grooves (initially, the USP was offered with lands and grooves, but after the first two years, that was changed to polygonal). Then, 9 barrels at a time are placed into one of the cold hammer forging machines, where 4 hammers take action, imparting 140 tons of pressure per beat and 1000 beats per minute. Once complete, these pistol barrels then have their chambers milled in another machine.

The slides are milled as well, from a solid block of steel and as a cost saving measure, the scraps from the chamber and slide milling process are sold back to the steel company. Designed around the higher pressures associated with the .40 S&W cartridge, the USP slide is rather large. Notable with the 9mm variant, that required slightly less weight to cycle reliably, a lightening cut was made into the underside of the slide (shown below). It was done both near the front of the slide, in an oval shaped cut out as well as the rear of the slide, next to the firing pin tunnel, opposite side of the extractor.

As reinforcement in key stress areas, laser hardening was placed in two locations: first, on the front edge of the ejection port area, where the barrel locks into place, in order to prevent cracking and chipping, and second, at the end of the firing pin tunnel, where the hammer makes contact with the firing pin. Finally, the extremely tough finish is applied, a nitro carburization process, where heat is applied with the finish, while oxygen is injected to aid in providing a better seal.

The receivers are created by pouring the polymer pellets into a clam-shaped mold, but to add strength in key areas, two steel inserts, one for the fire control assembly/ejector and one for the locking block and serial number plate, are injected just prior to pouring the mold. Though the .45 variant and compact USPs all are issued with steel magazines, the full size 9mm and .40 S&W variants have polymer magazines, but with steel inserts at the top portion, adding strength to the feed lip area (see polymer cutaway photo below).

Also, revolutionary at the time, was the incorporation of a relief port, just behind the breach face. Shown below, this area helped prevent “gunk” from building up within the firing pin channel and binding up the firing pin assembly, mainly found with poorer quality ammunition and lacquered bullets. Though not introduced into the USP until a few years after production began, so successful was this feature, that HK has since carried it over to their successive pistol line, as well as their long guns.

Once complete, each USP fires 17 rounds. The first 2 are for proofing and when complete a representative from the Ulm proof house then authorizes the proof stamp, the famous antlers, to be struck. The remaining 15 rounds, 5 for accuracy and 10 for reliability, are then fired. For accuracy, on the full size USP, 4 of 5 shots must not exceed 4.8” at 25m, whereas with the compact model, that spread is allowed to increase to 6.8”. For those who wonder about what hold is used when zeroing the USP at the factory, it is done with a 6 o’clock hold, POA/POI at 25m, firing FMJ ammunition.

Sight adjustments are made by the front and rear sights. Changes in elevation are made by removing the front sight and exchanging it for either a lower or higher sight. To raise the POI, replace with a shorter sight. To lower the POI, replace with a taller sight. Sights are offered in .2mm increments and each change of .2mm will affect the POI by 2” at 25m. For windage changes, simply shift the rear sight in the direction you want the round to shift. Sight heights are generally inscribed on the underside of the sights, but if you need to find out the height of your sight and that description is omitted, simply measure from the base of the sight to the top (see photo below).

When released, first in .40S&W and then shortly after in 9mm, the pistol was a huge success in the US market. Soon after, compact models followed of each, then came the full size and compact .45 variants. As mentioned previously, modularity was a key feature. The USP series is capable of being converted to 10 different variants, allowing traditional double action/single action, left and right side control levers, decock only, safety only, ambidextrous safety, and even a double action only (DAO), which due to its extremely heavy trigger pull was not a popular option and later discontinued. Yet, as the popularity of the pistol increased and more and more law enforcement purchases and contract began to materialize, a desire for an improved DAO system was realized. Enter the LEM or Law Enforcement Modification.

Developed especially for the US Immigration and Naturalization Service (INS), to improve trigger performance and reduce the trigger pull weight of DAO pistols, it quickly became a desired option and helped secure HK with the largest non-military pistol contract they had ever received. After 2001, it was also offered for the civilian market.

USP DA/SA and LEM Cutaway Pistols:

Since I regularly receive questions relating to understanding the operation of the LEM system and equally see many inaccurate descriptions presented “online”, I’ll explain here how it works:

The hammer in the LEM is a two-piece hammer comprised of a cocking piece (not visible when the pistol is assembled) and an external (visible) bobbed type hammer. The cocking piece and hammer are rotated rearward on the hammer axle when the slide moves to the rear. The LEM uses the rearward movement of the slide during loading and firing to fully compress the hammer spring instead of relying on the trigger pull in a conventional DA or DAO to compress the spring. The cocking piece is held in position by the sear and the hammer spring has been fully compressed by the hammer strut. Pulling the trigger rearward overcomes the trigger pull weight and disengages the passive safeties and the sear releases the cocking piece rotating the hammer forward on its axle under pressure of the compressed hammer spring imparted through the hammer strut to strike the firing pin.

As many have experienced, the LEM has many great features and benefits. I believe these to be the most significant:

-No external de-cocking or safety levers are needed (although external safeties can be assembled on some models if required, such as the USP).

-Consistent DAO trigger pull weight is reduced to approximately 7.5-8.5 pounds and a lighter trigger weight of approximately 5.5 pounds is also available.

-A safe length of free travel (slack) and a second stage of slightly heavier but consistent pull with every round fired.

-Short, consistent trigger reset distance normally associated with a single action (SA) pistol, enhancing the speed and accuracy of multiple follow up shots.

-Reliable, heavy hammer spring and hammer drop initiating the firing pin, even in adverse conditions.

-Fail safe, true, double action mode, should a primer fail to detonate on the first strike of the firing pin by simply pulling the trigger again.

Shown below is an early presentation of the multiple variants of which the USP can be set up. The introduction of LEM has since replaced the earlier DAO variants.

Safety is always a hallmark of Heckler and Koch weapons, and with the USP they raised the bar again. There are no fewer than eight safety measures in place on the USP:

-Disconnector: Ensures the slide is in battery, preventing out of battery fire. If the slide is more than 2.5mm back, the disconnector pushes down on the trigger bar, dropping it out of contact with the catch and thus, the sear.

-Firing Pin Spring: Preventing slam fire, it provides tension against the firing pin that must be overcome before the firing pin can strike the primer on a chambered cartridge.

-Firing Pin Block: Mounted horizontally within the slide, this prevents the firing pin from moving forward until the trigger is pulled. When the trigger is pulled, the reward movement of the trigger pulls the trigger bar forward, where it makes contact with the catch, forcing it up and in contact with the firing pin block, then pushing it up and out of the way of the firing pin.

-Catch: Mounted next to the disconnector, it disengages the firing pin block when the trigger bar is pulled (as described above).

-Sear Actuator Latch/Drop Safety: Dual purpose part that blocks the hammer from making contact with the firing pin until the trigger has been pulled. Mounted adjacent to the catch, when the trigger is pulled and the trigger bar pulls the catch up, pushing the firing pin block out of position, this part is correspondingly forced down. The downward movement drops the rear tip out of contact where it blocks the hammer and into a recess at the base of the hammer, allowing it to now move further forward and strike the firing pin. At the same time, at its opposite end, it makes contact with the sear roll pin and pushes the sear forward and out of contact with its interface point on the hammer (or contact piece, in LEM), allowing the hammer, under tension of the compressed hammer strut spring to fall forward and strike the firing pin.

-Safety: The external safety, as part of the control lever, prevents the trigger from being pulled until it is disengaged. When disengaged, a cavity in the hammer axle is presented to the catch, which allows for it to pivot under pressure from the trigger bar and trigger itself.

-Rubber Hammer Insert: Designed to both lighten the overall weight of the hammer (allowing for lighter overall trigger pull) and dissipate energy if the weapon is dropped on the hammer (better surviving drop tests, described shortly).

-Lock Out Device: The incorporation of the lock out device that has been built into the lanyard loop, when engaged, prevents the compression of the hammer spring and downward movement of the hammer strut.

*Of note, there is often much confusion surrounding the correct description of the Catch, Control Lever and Sear Actuator Latch. This is because of the multiple roles these parts fill and the fact that in initial introduction, they were a one piece item, simply referred to as the Catch. When, a couple years into production, this single part was separated into two parts, the confusion began. Mislabeled in multiple documents (owner’s manuals, maintenance manuals, spare parts lists and charts), they are usually referred to as the Catch or Control Lever, which as described above, is related to disengaging the firing pin block and the Catch, Sear Actuator Latch or Drop Safety, which blocks the hammer and pulls the sear out of its interface point with the hammer (or contact piece, in the case of LEM). Confusing, but it is best to be clear in describing the action the part provides during the discussion.

This is also a good place to discuss the Drop Test. This series of tests is actually a requirement from three different entities and is tied heavily into being able to be competitive for LE and military contracts. (Apparently people drop their pistols often and end up shooting themselves or others). This test, involves taking an empty cartridge casing, filling it with modeling clay and then inserting the casing into the chamber of the pistol. Then the pistol is dropped six times, once on the magazine, once on the sights, then on the back, front and each side. After each drop, the cartridge is inspected to see if the firing pin has imprinted on the clay in the position that would be the cap. For the NIJ Drop Test, the test is conducted from a height of 1 meter and dropped onto a hard, rubber plate. For the NATO Drop Test, the test is conducted from 1.5 meters and dropped onto concrete. And for the German TR Drop Test, the height is raised to 2 meters and dropped onto a steel plate. Often, people complain about why HK does not offer lighter trigger pulls on their USP and other pistols and the answer is from the results of these tests. HK designers have found that modifying internal components in order to provide a trigger pull of less than about 3.5 pounds makes it very difficult to pass these tests.

Another unique feature of the USP, actually designed as part of the MK23 program that was preceding the USP development, is the recoil reduction system or dual recoil rod assembly. The second stage helps significantly reduce the energy imparted on the receiver during firing. Activated twice during the 8 step cycle of operations, it allows the USP to exceed sustained use of +P and +P+ ammunition. Not found in the compact models, simply due to size limitations, instead, there you will find a polymer absorber bushing, which serves to prevent the tang on the front of the slide from impacting the receiver during recoil.

Another neat modular addition that was offered with the 9mm and .40 S&W USP full size pistols is the Jet Funnel Kit. This steel magazine well extension provides more grip space as well as a more effective insert point for rapid magazine changes. Adding it to the pistols prevented the use of the standard magazines, but instead incorporated either 18 rounds magazines for the 9mm and 16 round magazines for the .40 S&W. The photos below show the kit and the kit installed.

This photo shows the standard USP 9mm full size magazine, the original semi-translucent polymer Jet Funnel Kit magazine and the current production, steel Jet Funnel Kit magazine.

With almost 25 years of production and an extensive line of models that followed the initial full size model, including the Match, Elite, Expert and Tactical, it is clear the USP is a solid fan favorite.

Shown below is an early promotional photo of the Match.

Here is an Elite on my workbench.

And here is an advertisement for the limited edition anniversary model USP Compact.

Lastly, shown here is the USP Compact Tactical, with KAC suppressor, the predecessor to the HK45 Compact Tactical, later adopted for service with Naval Special Warfare Command.

*One note regarding the Tactical variants (9mm, .40 S&W and .45) due to the additional pressures associated with firing suppressed, these pistols are provided with specific caliber upgraded recoil rod assemblies. These can be identified by a single band or “cut” neat the end that locks up with the locking block. Though many owners are unaware of this upgraded part, and just drop in aftermarket threaded barrels to their standard USP pistols, doing so could cause permanent damage to their weapons.

Difficult to identify in this photo, but the top recoil rod assembly is the standard USP type, while the bottom one, with the circular band at near the end is the Tactical model.

And through this long period of production, HK has literally upgraded almost every internal component of the USP to improve its already stellar reliability and keep it current. This is one of the reasons why, even with so many newer options available from HK and other companies, they still receive regular orders for both new sales to the LE community and requests for this Armorer training.

For the Armorer training and maintenance of these pistols, HK provides several tools and gauges in order to ensure specific parts are within spec to ensure safe and reliable operation. Several are shown below. What I have found most impressive, specifically relating the bore and chamber “no go” gauges is just how many rounds would have to be fired before a barrel would be considered out of spec. Clearly, the amount of erosion would require a round count well north of 75,000.

Before moving on, I would be remiss to not mention the P8 and P10, German service variants of the USP. Of course, within HK USA, it is found amusing that the “US Pistol” would find service within Germany. From the USP, there are only a few minor differences. First, and most obvious, is the reversal of the control lever, with Safe being down and Fire being up. This was done because the German police and military units were, at the time, transitioning from post WWII Walther designs, which incorporated a slide mounted control lever in the same orientation. Next, the magazines (also shown below) are of a semi-translucent construction. And third, due to German directive, the barrels are conventional lands and grooves instead of polygonal.

Due to a character limit on this Forum, I was forced to split this report into two parts. Please find Part 2 here:

http://www.hkpro.com/forum/teufelsh...ufelshund-tactical/221991-notes-usp-p2000-hk45-p30-armorer-course-part-2-a.html