I am looking for pics, maybe a tutorial, on pressing a barrel with the trunnion already welded into the receiver. The only pics I can find are of pressing a barrel into a trunnion that has not been welded to the receiver yet.

Barrel press situp w/pics ?

1 reading

Flesh Thorn

Discussion starter

228 posts

·

Joined 2009

- Add to quote Only show this user

I am looking for pics, maybe a tutorial, on pressing a barrel with the trunnion already welded into the receiver. The only pics I can find are of pressing a barrel into a trunnion that has not been welded to the receiver yet.

32 posts

·

Joined 2008

+1

I would also like to know of any source for the receiver clamshell jig to use when pressing/removing the barrel pin.

I would also like to know of any source for the receiver clamshell jig to use when pressing/removing the barrel pin.

8,573 posts

·

Joined 2006

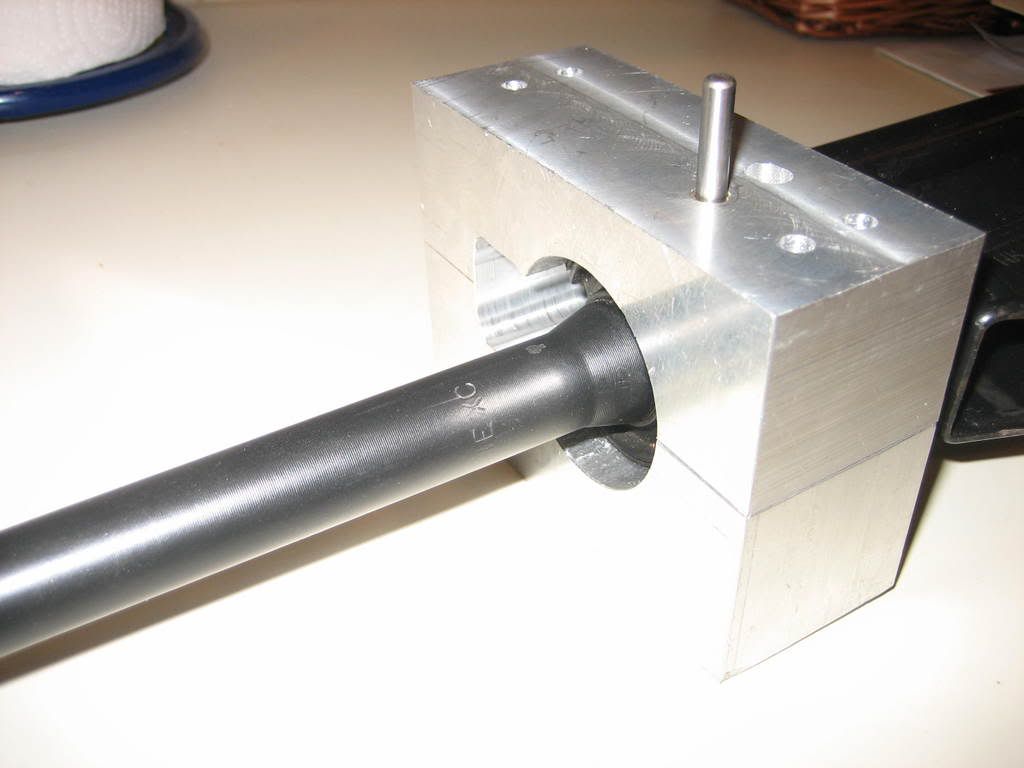

Ya mean like this one that I made:+1

I would also like to know of any source for the receiver clamshell jig to use when pressing/removing the barrel pin.

But pressing in a barrel is easy. Push the barrel in from the back side, the trunnion will sit on your press plates. Use a long piece of barstock to push between the press ram and the back of the barrel. As you start to get it pressed in far enough, start checking the bolt gap. Then push a little, then check. When the bolt gap gets down to .018-.020", stop. If it gets smaller than that, push the barrel all the way out and start over.

6,213 posts

·

Joined 2007

Oh you should definitely do that. You could probably sell it. But you wouldn't cause you're such a nice guy.

1,601 posts

·

Joined 2008

Flesh Thorn

Discussion starter

228 posts

·

Joined 2009

I am looking to pull the barrel on my KFM4, have the flutes fixed, and then reinstall barrel and triple frame. If I can manage the barrel pressing myself then I will go this route. Of course I would hate to ruin my $1300 target rifle chambered in American Eagle.

10,266 posts

·

Joined 2007

Of course I would hate to ruin my $1300 target rifle chambered in American Eagle.

!!! A$$hole... I almost hit my keyboard with coffee through the nose...

Bwahahaha "chambered in American Eagle"...

This post has been deleted

7,665 posts

·

Joined 2007

Ok, I don't know what make that rifle was... but I'll be dammed if they are that easy to remove! First one I ever removed, I bent the punch and broke 2 HHS endmills trying to cut out the center. I use an arbor press now... and even with that I about sh*t my pants cause I have to pull down on the bar so hard.Barrel removal

I still need to make a removal jig though. I have the aluminum block stock already cut to size and tapped/threaded... just need to cut the shape of the receiver and drill the guide holes.

Dave... got any measurments?

Flesh Thorn

Discussion starter

228 posts

·

Joined 2009

Exactly what I needed to see. Would a pic of your barrel pressing jig/plate be too much to ask for ?

1,254 posts

·

Joined 2007

It's the plate that came with the press. Has different shape cutouts.

3,038 posts

·

Joined 2008

Of course I would hate to ruin my $1300 target rifle chambered in American Eagle.[/QUOTE

LMAO

LMAO

19 posts

·

Joined 2009

those $100 shop press are real handy. Got mine from local harbor freight. Replaced my ak barrel pretty easy with it. Then when not working on weapons it changes out bearings and bends, breaks, straightens what ever needs done in the neighborhood. Those pins sometimes when you push them out the opposite direction they were pushed in they might get seized up in there. I usually try to push my pins in the same direction as it went in. unless its a tapered pin. Nice video's HART1. Now every time I see your post I will hear that voice in my head.

1,254 posts

·

Joined 2007

Dave,

Girly hammer. Come on man, your killing me. This is the way I have done all of my builds. Maybe 15 years as a millwright has given me stronger arms? Some have come out hard, but I do them all this way.

Removed my video's. Was just trying to help, but looks like my help isn't needed.

Girly hammer. Come on man, your killing me. This is the way I have done all of my builds. Maybe 15 years as a millwright has given me stronger arms? Some have come out hard, but I do them all this way.

Removed my video's. Was just trying to help, but looks like my help isn't needed.

8,573 posts

·

Joined 2006

Me too. Especially for people that haven't tried it yet, like the OP.

181 posts

·

Joined 2008

Nice barrel pin press Dave...That is the same one I ask you about a few months ago. Have you built any extras for sale. I know you were talking about it. Sure could use one! Please put me on the top of your retail list. My new hobby is collecting gunsmith tools.

2 posts

·

Joined 2008

+1

I’d also be interested in purchasing one of these jigs too.

This is slightly off the subject but…

Does anybody know of a source of a screw-type shop press? ( I’ve looked all over.)

I’d also be interested in purchasing one of these jigs too.

This is slightly off the subject but…

I’ve been told that a screw-type press is the best way to go, in regards to precisely attaining desired bolt gap, while pressing in barrels

.Does anybody know of a source of a screw-type shop press? ( I’ve looked all over.)

158 posts

·

Joined 2008

+1 here as well!!! That jig looks pretty slick.+1

I’d also be interested in purchasing one of these jigs too.

36 posts

·

Joined 2009

I took a scrap piece of 1 inch x 2 inch aluminum flat bar, and notched the end to fit in the magwell notch of the trunnion. That keeps the receiver from trying to rotate when installing the barrel pins. I might upgrade it to the clamshell type to make it even better.

So far as the screw method. Find a piece of all thread (Grade 8 or better, fine), about 6 inches longer than the barrel, that will fit thru the bore. Then find a piece of thick wall pipe the fits the trunnion cutouts in the front, and is an inch longer than the installed barrel sticking out of the trunnion. Couple nuts and heavy flat washers. One washer needs to be the same size as the chamber OD on the barrel, one needs to fit over your pipe. Pipe over barrel against trunnion. All thread thru bore, small washer and nut inside chamber, big washer and nut on other end. Turn until it comes out.

At least that is how I've seen it somewhere on the web.... I use a 20T press.

So far as the screw method. Find a piece of all thread (Grade 8 or better, fine), about 6 inches longer than the barrel, that will fit thru the bore. Then find a piece of thick wall pipe the fits the trunnion cutouts in the front, and is an inch longer than the installed barrel sticking out of the trunnion. Couple nuts and heavy flat washers. One washer needs to be the same size as the chamber OD on the barrel, one needs to fit over your pipe. Pipe over barrel against trunnion. All thread thru bore, small washer and nut inside chamber, big washer and nut on other end. Turn until it comes out.

At least that is how I've seen it somewhere on the web.... I use a 20T press.

103 posts

·

Joined 2006

My Barrel Press is a 12 ton press.

And my drill fixture uses Drill Bushings and a Cheapo Angle Vise, drilled at the correct height. A small amount of set up and that's it. The Bushing guide the pre-drill, Finish drill and Reamer.

It's not currently set up but you get the idea.

I also align my Receiver/ Cocking tube Welding set up with a length of 7/8" Dia Brass machined [stepped] to .729" for the tube at one end and .785" on the rest. This fits perfectly for PTR91 Receivers and just snug for SW 93 Receivers.

![Image]()

![Image]()

And my drill fixture uses Drill Bushings and a Cheapo Angle Vise, drilled at the correct height. A small amount of set up and that's it. The Bushing guide the pre-drill, Finish drill and Reamer.

It's not currently set up but you get the idea.

I also align my Receiver/ Cocking tube Welding set up with a length of 7/8" Dia Brass machined [stepped] to .729" for the tube at one end and .785" on the rest. This fits perfectly for PTR91 Receivers and just snug for SW 93 Receivers.

7 posts

·

Joined 2009

I am in the process of creating a SBR and want to remove my 16" barrel on my Coharie CA94 to be prepared for replacing it with an 8.5"barrel. Do I understand that the old barrel should be pressed into the receiver for removal? It appears that the front sight tower might be welded to the barrel which would make this impossible. Can/should I press the barrel out forward (from receiver toward muzzle) directionally speaking? Thoughts?

8,573 posts

·

Joined 2006

I always press them out from the inside out (push in the direction of the muzzle) and if there's no front sight, install from the same direction. If the front sight is already installed, then they can be installed from the front towards the back. It's just easier as far as fixturing goes to press from the inside out. At least, with the fixturing I've built it is.I am in the process of creating a SBR and want to remove my 16" barrel on my Coharie CA94 to be prepared for replacing it with an 8.5"barrel. Do I understand that the old barrel should be pressed into the receiver for removal? It appears that the front sight tower might be welded to the barrel which would make this impossible. Can/should I press the barrel out forward (from receiver toward muzzle) directionally speaking? Thoughts?

399 posts

·

Joined 2009

Actually, the AGI video doesn't deal with pressing a barrel at all. They show you how to grind/peel away the old receiver, fit the trunnion to a new cast or stamped receiver, and then prepare for welding or pinning in the case of the aluminum receiver. The welds are not covered, nor is pressing the barrel, and the original barrel pin is left in place. I purchased the video expecting the finer points of pressing barrels and the required press setup to be covered as well, but it's basically useless if you already have any kind of clue about how the rifle works. The AGI armorer's video also skips over the spring wrestling required for trigger pack D&A, probably because it would be too hard to avoid cursing on the video.

1,601 posts

·

Joined 2008

Bummer. I was thinking about getting it as I now own a bunch of parts kits. I've got a machine shop in my basement, and have a general idea on how the HK roller locking system all works, but was looking to learn some of the finer points of assembly but I guess the AGI dvd is not the way to learn it.Actually, the AGI video doesn't deal with pressing a barrel at all.

...but it's basically useless if you already have any kind of clue about how the rifle works. The AGI armorer's video also skips over the spring wrestling required for trigger pack D&A, probably because it would be too hard to avoid cursing on the video.

Learning the 'hard way' is potentially dangerous where firearms are involved.

54 posts

·

Joined 2009

? on Barrel pressing...

I over heard a friend at work talking a bearing on a Harley wheel and freezing before pressing....That got me to thinking What if ???....one were to freeze the barrel then take it to the press? would it give you more controll over the process of pressing a barrel? comments???? Don't mean to steel the thread...

I over heard a friend at work talking a bearing on a Harley wheel and freezing before pressing....That got me to thinking What if ???....one were to freeze the barrel then take it to the press? would it give you more controll over the process of pressing a barrel? comments???? Don't mean to steel the thread...

1,601 posts

·

Joined 2008

Depending on the fit between the parts, it may be required to heat one side and/or cool the other before attempting to press fit the parts. Or in cases of home mechanics that don't have high enough capacity presses it can make the fit a bit less tight so a lesser press can do the job.I over heard a friend at work talking a bearing on a Harley wheel and freezing before pressing....

However, and there is a really big however on this one. If you somehow get to the point where you haven't completed the pressing operation before the cold side gets warm, or hot gets cool you are now in a very bad place. Generally the fit is so tight at that point there is no way to un-do the assembly without destroying one, or both parts.

1,601 posts

·

Joined 2008

Aviatordave has a gage and he gets about 8,000 pounds of force before the barrel begins to move when he is removing a barrel from a rifle that has been shot a bunch.

I would suspect a MP5 barrel is a bit less tight, but a 9mm is .355 which means .25 all thread would be as large as you could likely use, and even at 4,000 lbs I think you'd be at risk of bending... consider this:

Would you jack your whole car up on a piece of all thread that was about the same diameter as a pencil?

A shop press from harbor freight can be had for $100-$150 I think it would be a wise investment for barrel pressing.

I would suspect a MP5 barrel is a bit less tight, but a 9mm is .355 which means .25 all thread would be as large as you could likely use, and even at 4,000 lbs I think you'd be at risk of bending... consider this:

Would you jack your whole car up on a piece of all thread that was about the same diameter as a pencil?

A shop press from harbor freight can be had for $100-$150 I think it would be a wise investment for barrel pressing.

8,573 posts

·

Joined 2006

I'm pretty sure you could install a barrel with all-thread, but if my gage is correct, I have serious doubts you could remove one that's been installed and shot much at all.

As mentioned by jdonovan, when I've pressed out barrels (and even the barrel pins for that matter), it takes 4 tons to get the first "pop" of movement. Then it's less than 1 ton the rest of the way out.

I just pulled the specs on Grade 2, 5, and 8 all-thread. Even with Grade 8 allthread, a 1/4-28 has a max tensile strength of around 2.5 tons. Common hardware store Grade 5 allthread is around 2 tons.

There wouldn't be an issue with bending, since you'll be pulling into place, the issue will be the ultimate yield strength of the all-thread.

As mentioned by jdonovan, when I've pressed out barrels (and even the barrel pins for that matter), it takes 4 tons to get the first "pop" of movement. Then it's less than 1 ton the rest of the way out.

I just pulled the specs on Grade 2, 5, and 8 all-thread. Even with Grade 8 allthread, a 1/4-28 has a max tensile strength of around 2.5 tons. Common hardware store Grade 5 allthread is around 2 tons.

There wouldn't be an issue with bending, since you'll be pulling into place, the issue will be the ultimate yield strength of the all-thread.

54 posts

·

Joined 2011

Boy if someone would make a tool kit and video....

If someone would make a set of tools and a video on rebarreling MP5's or similar that would be something I would LOVE!!! I can knock out a barrel no problem, but getting a new one pressed in the correct depth and then remachining a notch for the retaining pin, thats what seems to be the trick in my book. Anyone who can assist with this, I would even travel to see someone do this and do a "class" on the subject I would video it and all that stuff. :wink:

If someone would make a set of tools and a video on rebarreling MP5's or similar that would be something I would LOVE!!! I can knock out a barrel no problem, but getting a new one pressed in the correct depth and then remachining a notch for the retaining pin, thats what seems to be the trick in my book. Anyone who can assist with this, I would even travel to see someone do this and do a "class" on the subject I would video it and all that stuff. :wink:

200 posts

·

Joined 2009

Are you working on a 9mm or .40? Different process......the .40 uses bullet guides that will not allow the barrel to pass through the reciever. It is really not all that difficult to install the barrel as indicated earlier. It just takes a little time and patience. Press it in, check bolt gap, repeat as required until desired bolt gap is achieved. mill and drill barrel pin. Do you have access to a hydraulic press? Other machine shop equipment or large drill press? Unless you have an undying desire to do it all yourself.......rather than spending several hundred on tooling and airfair or worse.....gasoline for the car, consider sending it to a member who is reputable to have the work done. Just send barrel. receiver, bolt assembly. It would cost far less to do it that way. It would not be worth buying a bunch of tools for 1 or 2 builds

54 posts

·

Joined 2011

I am talking about a 9mm set up. I would want to know how much headspace is required and how to measure it. That much, I think, can be covered in a breif description on the web. However how to drill the cross pin is a bit trickier I would guess since the hole for the trunnion is already drilled and the barrel has not been drilled. So as you said, I do in fact have an undying desire to do it myself, and I have a full machine shop at my disposal including a press. For me, I think, it would be worth air fair if I had the right person explain how to do this. I don't seem to be able to find anyone who can adequately explain the process and no one makes a video!

200 posts

·

Joined 2009

If you can get the barrel into place with a gap of .018- .020 between the back of the bolt head and the front of the carrier while the bolt is in battery, ( I usually try and add .001-.002 to allow for set in) measured through the mag well with feeler gauges, set the barreled action in the mill and level across the bolt rails and verify again across the side of the magwell. Find center of the barrel pin hole. I use a drill blank for this. Use a center cutting endmill smaller than barrel pin (approx 5/32) to plunge into the barrel, this creates a flat spot for the drill bit so it does not wander. I usually plunge as far as possible. Without moving anything switch to a #9 Carbide drill to finish enlarging the hole and finish the passage through the barrel. Apply anti-sieze to the pin and carefully drive it through the channel. The whole process of cutting the hole takes about five minutes and is no big issue, but then again everything is easy when you know how

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2M

- members

- 97K

- Since

- 2000

Actually created in 1999 (the original posts from the first database were lost), we are a forum dedicated to and laser-focused on Heckler & Koch firearms, Heckler & Koch accessories and the owners and enthusiasts that love them! Come join the discussion regarding HK pistols, long arms, NFA arms, HK accessories, HK history and trivia and more.

Explore Our Forums