Part 2: Due to a character limit on this Forum, I was forced to split this report into two parts. If you have not done so already, please read Part 1 first; found here:

http://www.hkpro.com/forum/teufelsh...ufelshund-tactical/221990-notes-usp-p2000-hk45-p30-armorer-course-part-1-a.html

P2000

From the success of the USP series, came the P2000. Originally designed for the German Customs organization, it was basically a requirement for an updated, more ergonomic version of the USP Compact, contoured for carry, adding a customizable grip and replacing the proprietary mounting rail with the one specific to a light they requested. Beyond securing this contract, it was the P2000, along with a number of the later introduced P2000SK as well as USP Compact LEM, that won the DHS/ICE contract discussed previously; a massive contract for the company. For that contract and for US civilian importation, the mounting rail was modified again to what was termed the “industry standard”, allowing access to a much wider range of products.

Though rarely seen and extremely unusual is the original design request from German Customs. They wanted the LEM variant, which in Germany is referred to as CDA or Combat Defense Action, but oddly enough they also wanted a spurred hammer, side mounted safety lever and a rear mounted decocking lever, all three normally associated with DA/SA operation. Apparently, if you place a large enough order, HK will put any additional safety points on your pistol, regardless of how unusual they are. Below is a cutaway drawing of that specific variant. Though the side mounted safety lever is omitted to not block the internal components, clearly seen is the spurred hammer, LEM components and decocking lever. Also seen is the unique rail point, designed for the German issue light.

![Image]()

Once specifically unique item added to the P2000 and P2000SK pistols that were delivered to the DHS/ICE contract was the inclusion of a small transponder chip into the left side of the steel insert of the grip frame. This can be seen in the photo of the cutaway training guns below. This chip served as an electronic gun data book, assessable from a PDA. It is unclear how extensively this option was exercised, but it was in the statement of work, so HK provided it.

![Image]()

Other updates that were incorporated with the P2000 series included adding rubber base plates for the magazines. This helped dissipate energy during a magazine drop during reloads, thus extending the life of the magazines, as well as aiding in passing the Drop Test requirements described earlier.

Within the slide, a minor upgrade came in the form of a polymer buffer that works in concert with the extractor spring. It reinforces that spring, reducing its wear and providing more force against the extractor, while also preventing the extractor from over extension.

Also, and rather interesting, is that all P2000 pistols have the ability to accept an optional retro-fit magazine disconnect kit. If you look inside the right side of the receiver, you will clearly see the shelf and mounting point. This design, popular with US Department of Corrections, where fear that an inmate may get a hold of an officer’s pistol, locks the action of the pistol when the magazine is removed. Therefore, in a situation where an officer was about to lose control of his weapon, he need only to release the magazine to render his weapon inoperable. Of note, HK created a somewhat less refined version of this for a previous contract for USP pistols for the Department of Corrections, but instead of preventing the trigger bar from moving like in the P2000, in the USP retrofit, it had a bar that went over the sear, blocking the hammer’s forward movement. HK designers moved away from this design when creating it for the P2000, as they found that over time the USP design caused more pressure on the leading edge of the sear against the flat main spring, and as such, a higher failure rate of the flat main spring.

As part of the contouring of the P2000 series came the removal of a side mounted safety and decocker for DA/SA and in its place was a rear mounted decocker, which when activated, forces the sear out of its contact point with the hammer. Also, different on the P2000 series was a lack of modularity, in the fact that no longer was the base pistol capable of being converted between DA/SA and LEM (it can be done, but not approved by HK). With different frames, you are either left with the choice of one or the other.

Along the contouring line also came and update to the grips, with a new side grip design that carried over to the MP7 production and a removable and exchangeable rear grip panel, allowing the shooter to customize the grip size to one of four sizes. With this customization also came the recognition of a requirement for ambidextrous use, and the incorporation of a slide release now mounted on the right side of the weapon. Of note, HK recommends that you do not remove the right side slide release for normal maintenance. It is not fitted into a steel insert, only polymer, and repeated removal will loosen the tolerances, resulting in a “rattle” of that part against the weapon.

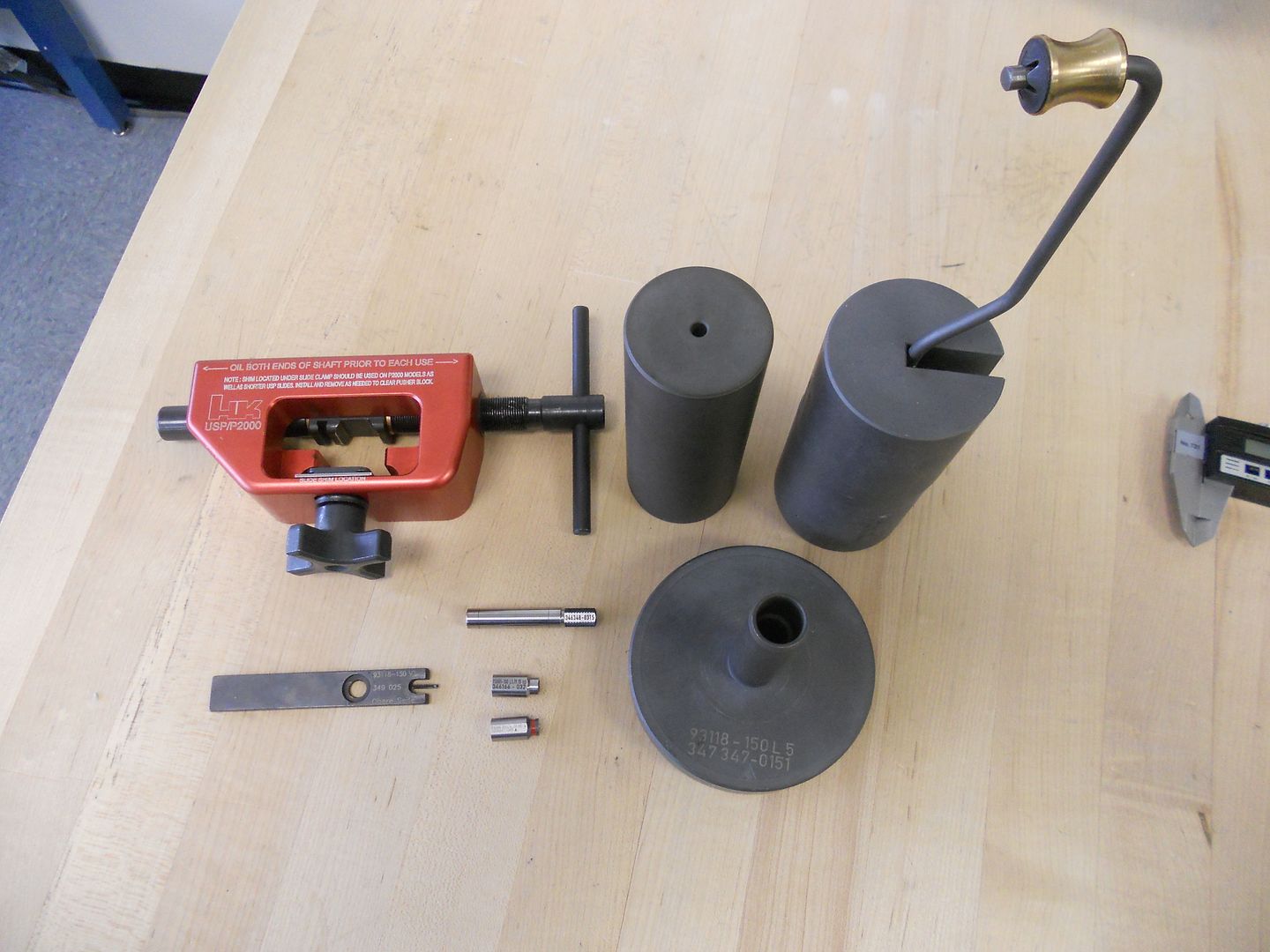

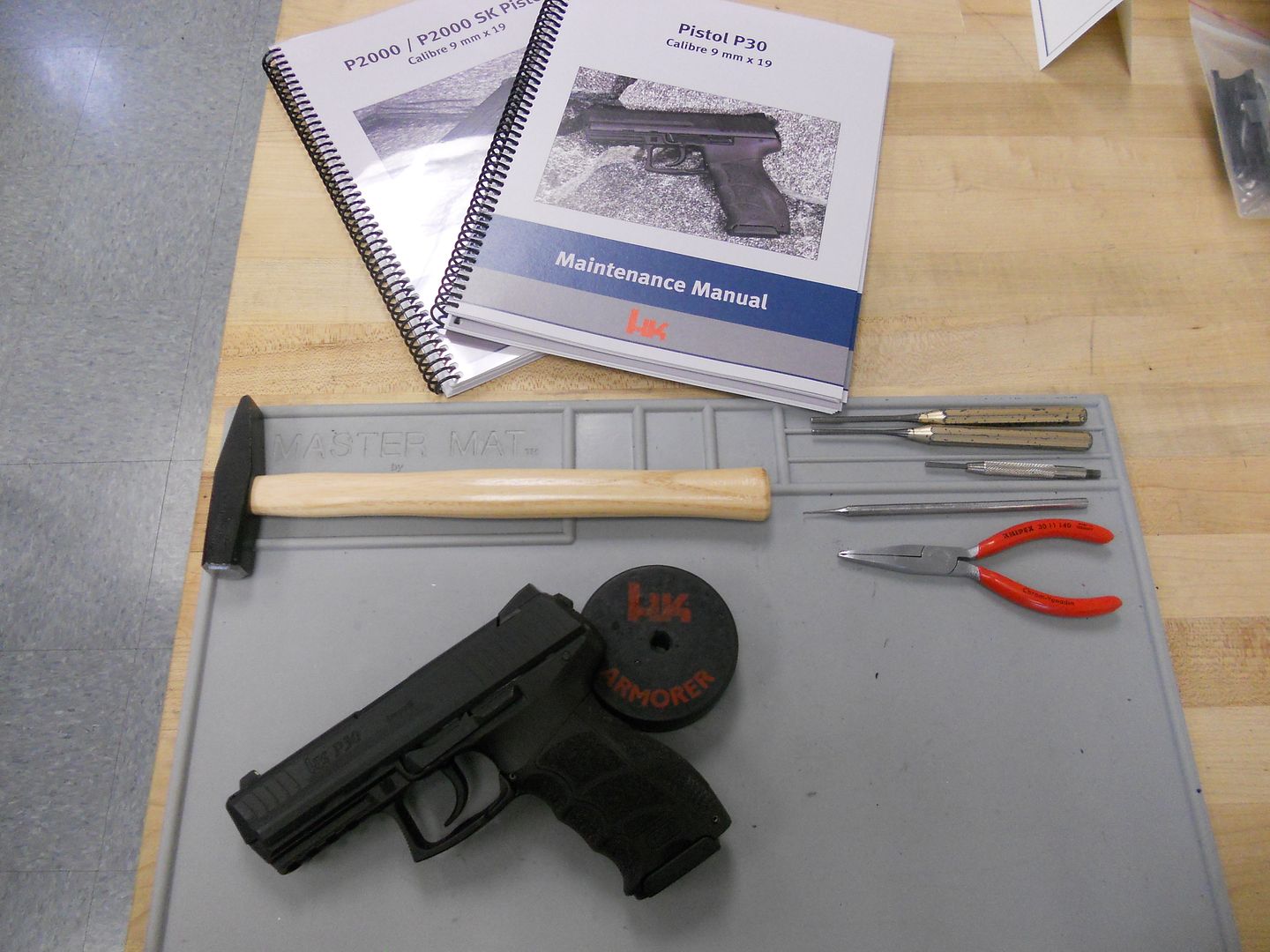

Below is a photo of some of the many tools and gauges specific to maintaining the P2000 series. Similar tools are provided by HK for each of their weapons.

![Image]()

HK45

Next in the HK pistol line came the HK45 and HK45 Compact. Developed as product improvements over the earlier USP .45 and .45 Compact for first the Joint Combat Pistol Program (JCCP) and then continued into the Combat Pistol Program (CPP) after SOCOM pulled out. Despite the failure of these programs to provide DoD with a replacement for the M9 service pistol, HK decided to release these pistols into the civilian product line as a way to recoup the expenses incurred in the development.

Of unique interest, though the civilian import HK pistols are all marked on their receiver mounted serial number insert with “HKI — Columbus, GA” to designate the US import location for that product line, the HK45 Armorer pistol I was issued with for training was one of the original test pistols from the JCCP. Note the import location in the photo below, denoting the HK Defense Arm of HK USA, in Ashburn, VA.

![Image]()

Incorporating almost all of the same proven internal components as its predecessor, the USP .45, the most noticeable differences appear externally. Like the P2000 that preceded it, a heavy focus was placed on contouring the weapon. The slide received front serrations and the sights and their dovetail within the slide were enlarged. As an improvement over the previous standard sights, for the HK45 series, HK debuted new non-radioactive Luminova sights, as well as a more traditional tritium option.

On the frame came the incorporation of a true picantinny rail, as well as a carryover of the ambidextrous slide release from the P2000 development. A new, longer ambidextrous magazine release was included, as well as, on the DA/SA variants, an updated, slim line control lever.

![Image]()

Clearly, the biggest change, at least with the full size HK45, is in the grip. Unlike the HK45C, which received a carryover design from the P2000, the HK45 incorporated an entirely new design. Reaching back to a long established relationship with Karl Nill, who many of you know of from the wooden grips he designed for the PSG1, P9S and P7 series guns, he was contracted to design what has since been unofficially termed the “spiderman grips”. Contoured finger grooves on the front combined with a new side grip texture and exchangeable rear grip panels make the HK45 much more ergonomic and comfortable to shoot. Below are phots of both the HK45 and HK45C, illustrating the differences in the grip design.

![Image]()

![Image]()

Part of the redesign of the grips that began with the P2000 series, was the access to the hammer strut and spring. With the P2000, when you removed the rear grip panel, the hammer strut and spring were released as well. As a result of many customer complaints regarding not feeling confident about properly reassembling those parts after swapping out rear grip panels, for the HK45 series, HK designers developed a secondary capture point underneath the rear grip panel to capture the hammer strut and spring even when the rear grip panel is removed.

Tactical models of both the HK45 and HK45C have been offered, which incorporate a threaded barrel and all models, regardless of barrel size, include HK’s proprietary O ring. This design feature, first pioneered to exceed accuracy requirements necessary for the MK23 program, ensures that, at the moment of ignition of a firing cartridge, the barrel and slide have a secure lock up. Shown below, note the O ring in the standard HK45 barrel.

![Image]()

The HK45C (Tactical), in DA/SA configuration, with decock only control lever function (as an easy transition from their Sig P226 pistols) has been adopted by US Navy Special Warfare Command and designated at the MK24; apparently, a better fit size-wise than their previous MK23 pistols.

Of specific note, with the HK45 series pistols, though originally produced in Germany, these are currently, the only HK pistols “manufactured” in the US, at HK’s Newington, NH location. In “manufactured”, it is meant that the mold is poured in Newington and then the parts, which all are manufactured in Germany, are assembled to create the finished product. These guns can be distinguished from the “all German” pistols by their serial numbers and slide markings.

P30

Initially labeled the P3000, the P30 was designed for a contract for the German Federal Police (formerly Border Guards). Very similar to the P2000 series internally, as you would expect, there are several upgrades. Though the ambidextrous slide release was maintained, the contract for the Federal Police required that the left side slide release lever, which serves the dual purpose as the takedown lever, be semi-captive, so that it could not inadvertently be removed. Working in combination with a cut out on the bottom of the locking block, as part of that redesign, the trigger return spring was modified, in that the dead leg was extended to place additional pressure on a specific area of the slide release axle. As such, you will notice that with the P30 series, the trigger return spring has a reverse orientation of its legs than the pistols that preceded it.

![Image]()

Also relating to the slide release, with the P30 series, three length options were developed to further customize the pistol to its end user, a small, medium and long (standard) length. I have found that with my grip, I often place pressure on the slide release while shooting and thus defeat its operation when the last round of a magazine has been fired. Modifying my pistol to the medium length helps correct that issue, but I have found the short length option to require me to shift my hand out of position in order to actuate it. Regardless, I enjoy having the options.

In line with a concern for parts working themselves free, the P30 series sear axle was tapered on one end, so that it is directional in its placement (a good thing to know for you guys who like to disassembly your HK pistols).

![Image]()

The “spiderman” grip design from Karl Nill on the HK45 was brought forward, with an additional customization feature of removable side panels, offered in three sizes. In combination with the 3 back panels, a user has 27 different options available for a custom fit.

Offered in three sizes, as the P30, which falls slightly larger than a P2000 and slightly smaller than a USP full size, a long slide variant, the P30L and most recently in a sub-compact variant, the P30SK, with similar dimensions as the P2000SK that preceded it. Seen below are photos of two the recently released P30SK. (Notice the very low serial number on the pistol on the right and the absence of marking on the pistol on the left). Like the full size variants, it is offered in DA/SA, LEM and DA/SA with an external safety.

![Image]()

The most notable internal upgrade with the P30SK is the addition of a secondary firing pin safety (shown below), designed to further increase the safety of that assembly, during the most critical portion of the drop test mentioned previously, specifically, the drop onto the rear sights.

![Image]()

Guess who is a happy HK Armorer?

![Image]()

One other point that became standard with the P30 series, and now throughout the entire pistol production line, is the incorporation of a black, “maritime” finish on the internal components. Why, of course you might ask? Hard core HK fans will remember that HK had pioneered this application back in the 80s for the US Navy SEALs, German Kampschwimmer and several other organizations who needed additional corrosion resistance on their weapons, due to their subsurface mission. Could the same now be a major concern for the P30 and other HK pistols? Nope, instead, HK had found that there had been a rise in organizations, who don’t like to focus much time on proper weapons maintenance, were taking their issued P30 pistols and without disassembling them, were dunking them into solvent tanks. Then they would remove them, shake them off and without any sort of re-lube, were just loading them and placing them back in their holsters. This process, in combination with the more tropical climate where they operated, led to, as you might expect, reliability issues. Thus, the coating is now standard.

Though, clearly not an all-inclusive wrap of these excellent pistols, this certainly covers the main points and with a max word count restriction for posts here, I can only go so in depth with history and discussion. Still, I’m confident that after reading this, learning has occurred and hopefully, you are left with a greater appreciation for the design of these pistols and Heckler and Koch’s focus on providing the best and most innovative weapons.

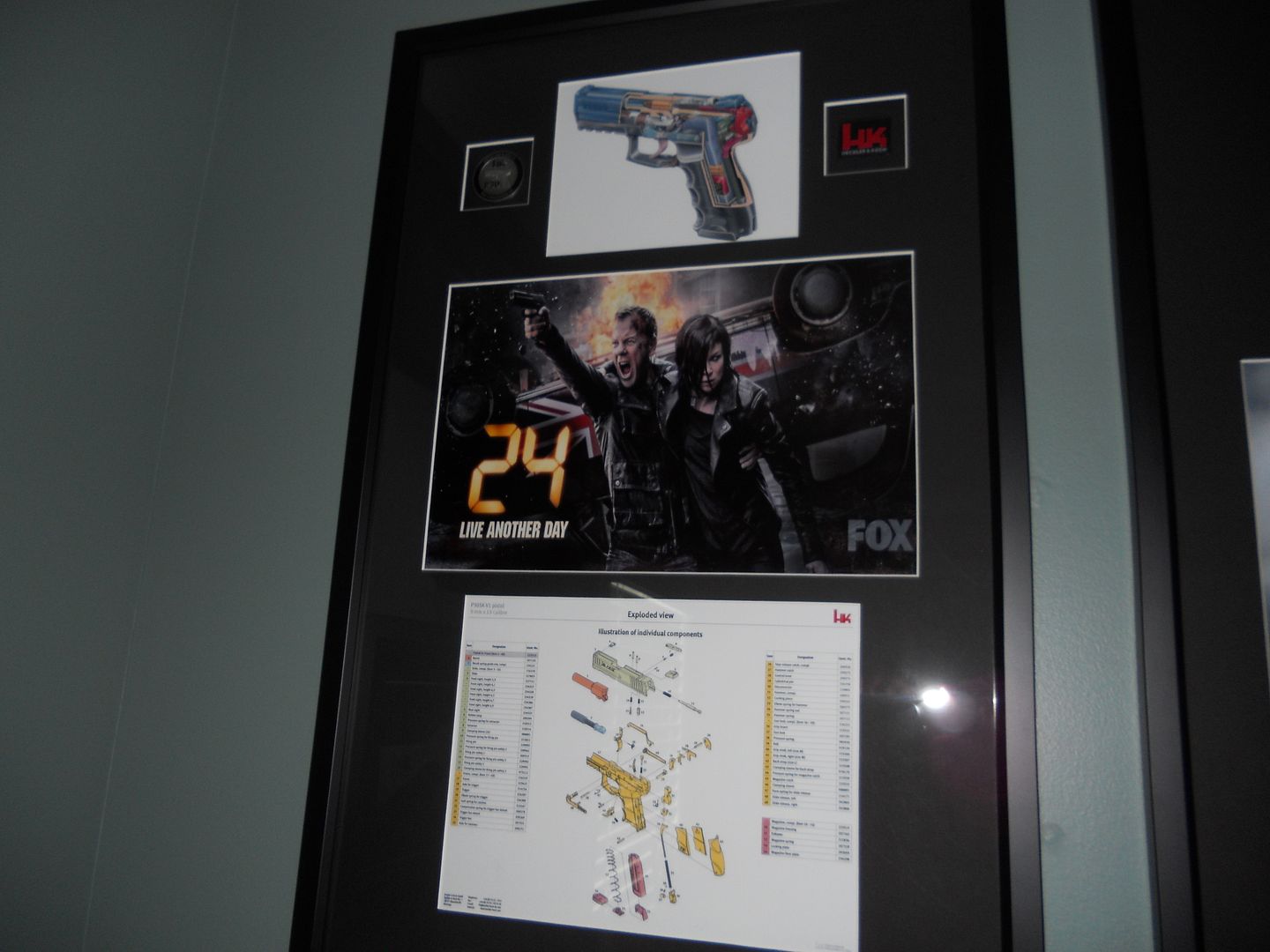

In keeping with my own tradition of commemorating completion and certification of each Armorer Course, here are the custom frames I created for these pistols (this process takes time and effort. As such, I’m still getting the items together for the HK45).

![Image]()

![Image]()

![Image]()

http://www.hkpro.com/forum/teufelsh...ufelshund-tactical/221990-notes-usp-p2000-hk45-p30-armorer-course-part-1-a.html

P2000

From the success of the USP series, came the P2000. Originally designed for the German Customs organization, it was basically a requirement for an updated, more ergonomic version of the USP Compact, contoured for carry, adding a customizable grip and replacing the proprietary mounting rail with the one specific to a light they requested. Beyond securing this contract, it was the P2000, along with a number of the later introduced P2000SK as well as USP Compact LEM, that won the DHS/ICE contract discussed previously; a massive contract for the company. For that contract and for US civilian importation, the mounting rail was modified again to what was termed the “industry standard”, allowing access to a much wider range of products.

Though rarely seen and extremely unusual is the original design request from German Customs. They wanted the LEM variant, which in Germany is referred to as CDA or Combat Defense Action, but oddly enough they also wanted a spurred hammer, side mounted safety lever and a rear mounted decocking lever, all three normally associated with DA/SA operation. Apparently, if you place a large enough order, HK will put any additional safety points on your pistol, regardless of how unusual they are. Below is a cutaway drawing of that specific variant. Though the side mounted safety lever is omitted to not block the internal components, clearly seen is the spurred hammer, LEM components and decocking lever. Also seen is the unique rail point, designed for the German issue light.

Once specifically unique item added to the P2000 and P2000SK pistols that were delivered to the DHS/ICE contract was the inclusion of a small transponder chip into the left side of the steel insert of the grip frame. This can be seen in the photo of the cutaway training guns below. This chip served as an electronic gun data book, assessable from a PDA. It is unclear how extensively this option was exercised, but it was in the statement of work, so HK provided it.

Other updates that were incorporated with the P2000 series included adding rubber base plates for the magazines. This helped dissipate energy during a magazine drop during reloads, thus extending the life of the magazines, as well as aiding in passing the Drop Test requirements described earlier.

Within the slide, a minor upgrade came in the form of a polymer buffer that works in concert with the extractor spring. It reinforces that spring, reducing its wear and providing more force against the extractor, while also preventing the extractor from over extension.

Also, and rather interesting, is that all P2000 pistols have the ability to accept an optional retro-fit magazine disconnect kit. If you look inside the right side of the receiver, you will clearly see the shelf and mounting point. This design, popular with US Department of Corrections, where fear that an inmate may get a hold of an officer’s pistol, locks the action of the pistol when the magazine is removed. Therefore, in a situation where an officer was about to lose control of his weapon, he need only to release the magazine to render his weapon inoperable. Of note, HK created a somewhat less refined version of this for a previous contract for USP pistols for the Department of Corrections, but instead of preventing the trigger bar from moving like in the P2000, in the USP retrofit, it had a bar that went over the sear, blocking the hammer’s forward movement. HK designers moved away from this design when creating it for the P2000, as they found that over time the USP design caused more pressure on the leading edge of the sear against the flat main spring, and as such, a higher failure rate of the flat main spring.

As part of the contouring of the P2000 series came the removal of a side mounted safety and decocker for DA/SA and in its place was a rear mounted decocker, which when activated, forces the sear out of its contact point with the hammer. Also, different on the P2000 series was a lack of modularity, in the fact that no longer was the base pistol capable of being converted between DA/SA and LEM (it can be done, but not approved by HK). With different frames, you are either left with the choice of one or the other.

Along the contouring line also came and update to the grips, with a new side grip design that carried over to the MP7 production and a removable and exchangeable rear grip panel, allowing the shooter to customize the grip size to one of four sizes. With this customization also came the recognition of a requirement for ambidextrous use, and the incorporation of a slide release now mounted on the right side of the weapon. Of note, HK recommends that you do not remove the right side slide release for normal maintenance. It is not fitted into a steel insert, only polymer, and repeated removal will loosen the tolerances, resulting in a “rattle” of that part against the weapon.

Below is a photo of some of the many tools and gauges specific to maintaining the P2000 series. Similar tools are provided by HK for each of their weapons.

HK45

Next in the HK pistol line came the HK45 and HK45 Compact. Developed as product improvements over the earlier USP .45 and .45 Compact for first the Joint Combat Pistol Program (JCCP) and then continued into the Combat Pistol Program (CPP) after SOCOM pulled out. Despite the failure of these programs to provide DoD with a replacement for the M9 service pistol, HK decided to release these pistols into the civilian product line as a way to recoup the expenses incurred in the development.

Of unique interest, though the civilian import HK pistols are all marked on their receiver mounted serial number insert with “HKI — Columbus, GA” to designate the US import location for that product line, the HK45 Armorer pistol I was issued with for training was one of the original test pistols from the JCCP. Note the import location in the photo below, denoting the HK Defense Arm of HK USA, in Ashburn, VA.

Incorporating almost all of the same proven internal components as its predecessor, the USP .45, the most noticeable differences appear externally. Like the P2000 that preceded it, a heavy focus was placed on contouring the weapon. The slide received front serrations and the sights and their dovetail within the slide were enlarged. As an improvement over the previous standard sights, for the HK45 series, HK debuted new non-radioactive Luminova sights, as well as a more traditional tritium option.

On the frame came the incorporation of a true picantinny rail, as well as a carryover of the ambidextrous slide release from the P2000 development. A new, longer ambidextrous magazine release was included, as well as, on the DA/SA variants, an updated, slim line control lever.

Clearly, the biggest change, at least with the full size HK45, is in the grip. Unlike the HK45C, which received a carryover design from the P2000, the HK45 incorporated an entirely new design. Reaching back to a long established relationship with Karl Nill, who many of you know of from the wooden grips he designed for the PSG1, P9S and P7 series guns, he was contracted to design what has since been unofficially termed the “spiderman grips”. Contoured finger grooves on the front combined with a new side grip texture and exchangeable rear grip panels make the HK45 much more ergonomic and comfortable to shoot. Below are phots of both the HK45 and HK45C, illustrating the differences in the grip design.

Part of the redesign of the grips that began with the P2000 series, was the access to the hammer strut and spring. With the P2000, when you removed the rear grip panel, the hammer strut and spring were released as well. As a result of many customer complaints regarding not feeling confident about properly reassembling those parts after swapping out rear grip panels, for the HK45 series, HK designers developed a secondary capture point underneath the rear grip panel to capture the hammer strut and spring even when the rear grip panel is removed.

Tactical models of both the HK45 and HK45C have been offered, which incorporate a threaded barrel and all models, regardless of barrel size, include HK’s proprietary O ring. This design feature, first pioneered to exceed accuracy requirements necessary for the MK23 program, ensures that, at the moment of ignition of a firing cartridge, the barrel and slide have a secure lock up. Shown below, note the O ring in the standard HK45 barrel.

The HK45C (Tactical), in DA/SA configuration, with decock only control lever function (as an easy transition from their Sig P226 pistols) has been adopted by US Navy Special Warfare Command and designated at the MK24; apparently, a better fit size-wise than their previous MK23 pistols.

Of specific note, with the HK45 series pistols, though originally produced in Germany, these are currently, the only HK pistols “manufactured” in the US, at HK’s Newington, NH location. In “manufactured”, it is meant that the mold is poured in Newington and then the parts, which all are manufactured in Germany, are assembled to create the finished product. These guns can be distinguished from the “all German” pistols by their serial numbers and slide markings.

P30

Initially labeled the P3000, the P30 was designed for a contract for the German Federal Police (formerly Border Guards). Very similar to the P2000 series internally, as you would expect, there are several upgrades. Though the ambidextrous slide release was maintained, the contract for the Federal Police required that the left side slide release lever, which serves the dual purpose as the takedown lever, be semi-captive, so that it could not inadvertently be removed. Working in combination with a cut out on the bottom of the locking block, as part of that redesign, the trigger return spring was modified, in that the dead leg was extended to place additional pressure on a specific area of the slide release axle. As such, you will notice that with the P30 series, the trigger return spring has a reverse orientation of its legs than the pistols that preceded it.

Also relating to the slide release, with the P30 series, three length options were developed to further customize the pistol to its end user, a small, medium and long (standard) length. I have found that with my grip, I often place pressure on the slide release while shooting and thus defeat its operation when the last round of a magazine has been fired. Modifying my pistol to the medium length helps correct that issue, but I have found the short length option to require me to shift my hand out of position in order to actuate it. Regardless, I enjoy having the options.

In line with a concern for parts working themselves free, the P30 series sear axle was tapered on one end, so that it is directional in its placement (a good thing to know for you guys who like to disassembly your HK pistols).

The “spiderman” grip design from Karl Nill on the HK45 was brought forward, with an additional customization feature of removable side panels, offered in three sizes. In combination with the 3 back panels, a user has 27 different options available for a custom fit.

Offered in three sizes, as the P30, which falls slightly larger than a P2000 and slightly smaller than a USP full size, a long slide variant, the P30L and most recently in a sub-compact variant, the P30SK, with similar dimensions as the P2000SK that preceded it. Seen below are photos of two the recently released P30SK. (Notice the very low serial number on the pistol on the right and the absence of marking on the pistol on the left). Like the full size variants, it is offered in DA/SA, LEM and DA/SA with an external safety.

The most notable internal upgrade with the P30SK is the addition of a secondary firing pin safety (shown below), designed to further increase the safety of that assembly, during the most critical portion of the drop test mentioned previously, specifically, the drop onto the rear sights.

Guess who is a happy HK Armorer?

One other point that became standard with the P30 series, and now throughout the entire pistol production line, is the incorporation of a black, “maritime” finish on the internal components. Why, of course you might ask? Hard core HK fans will remember that HK had pioneered this application back in the 80s for the US Navy SEALs, German Kampschwimmer and several other organizations who needed additional corrosion resistance on their weapons, due to their subsurface mission. Could the same now be a major concern for the P30 and other HK pistols? Nope, instead, HK had found that there had been a rise in organizations, who don’t like to focus much time on proper weapons maintenance, were taking their issued P30 pistols and without disassembling them, were dunking them into solvent tanks. Then they would remove them, shake them off and without any sort of re-lube, were just loading them and placing them back in their holsters. This process, in combination with the more tropical climate where they operated, led to, as you might expect, reliability issues. Thus, the coating is now standard.

Though, clearly not an all-inclusive wrap of these excellent pistols, this certainly covers the main points and with a max word count restriction for posts here, I can only go so in depth with history and discussion. Still, I’m confident that after reading this, learning has occurred and hopefully, you are left with a greater appreciation for the design of these pistols and Heckler and Koch’s focus on providing the best and most innovative weapons.

In keeping with my own tradition of commemorating completion and certification of each Armorer Course, here are the custom frames I created for these pistols (this process takes time and effort. As such, I’m still getting the items together for the HK45).